MB8-100T3200 Electric CNC Press Brake,Sheet Metal Bending Machine for Sale

MB8-100T3200 Electric CNC Press Brake,Sheet Metal Bending Machine for Sale

The main structure and performance of the machine:

The machine is designed and manufactured using the latest technology from KRRASS, CHINA, ensuring the strength, rigidity and safety of the machine. Machine tool shape is simple and beautiful, exquisite workmanship, mechanical processing, assembly of components, etc. are all fine work. The machine adopts the whole high-quality steel plate welding structure, the frame is thick and rigid, the machine surface sprayed with imported rust-proof primer and finish to make the machine last as long as new. Rack and upper work slider using imported large-scale CNC floor boring milling and other precision machining to ensure the location of each mounting surface requirements.

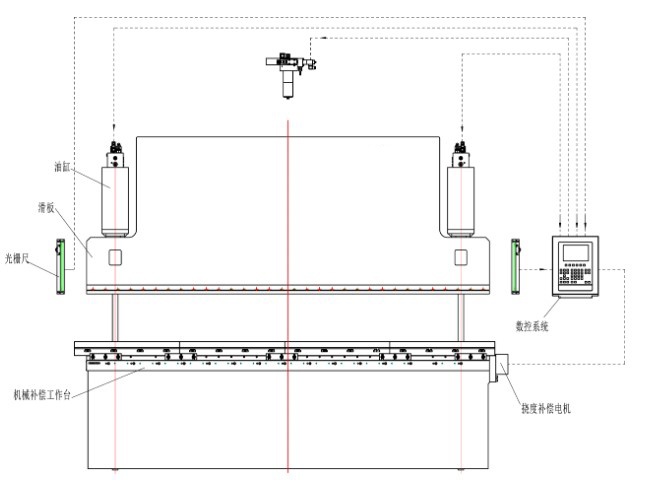

The machine is mainly composed of rack, skateboard, rear bezel system, slider and synchronous control device, mold, control system, etc.:

(1) Rack part: This part is a frame structure, composed of work bench, left and right side plate, join beam, mechanical compensation device, etc. The use of steel plate overall welding, good rigidity, high strength, has a good ability to resist distortion and deformation, and through the surface projectile treatment and other processes to eliminate internal stress, to ensure the overall accuracy of the machine tool lasting stability;

(2) Upper skateboard part: left and right cylinder with bolts and frame fastening joint, cylinder piston rod and slider using sphericic pad and screw joint, the structure enables the slider to withstand bias can improve the working status of the piston rod and piston rod and slider binding performance; The slider and the frame are sub-joined by a rectangular rail with self-lubricating function, and a grating ruler with a measurement accuracy of 0.005mm is installed on the C-plate on both sides of the rack to detect and feedback the simultaneous motion of the two cylinders in order to control the travel position of the slider.

(3) Mold and clamping device: the mold consists of two parts of the upper mold and the lower mold, using the overall quenching, durable. The upper mold is mounted on the slider, and is fixed by the fast press plate clamping device, and the lower die is in the form of a comodulation mode, which is convenient and fast to change the mold, reducing labor intensity and improving production efficiency.

(4) Front support bracket: This part is standard part, installed on the front of the work station. When used, the lift holder can be manually moved to the appropriate position for fastening according to the length of the work, and the carrier can be adjusted horizontally and vertically.

(5) Special structure of the throat deformation compensation device: each side of the machine installed a grating ruler, used to measure and feedback the precise distance between the slider and the lower work station. The grating ruler is connected with the workbench by C-frame, which eliminates the effect of rack throat deformation on the position of the slider, the position data of the slider is fed back to the CNC system when the slider is running, and the operation of the proportional servo valve is controlled by the CNC system output signal, which controls the movement of two sets of proportional servo valves respectively, so that the two cylinders maintain precise synchronization.

This structure enables the machine to be anti-biased and effectively prevents non-standard work items from colliding with the grating ruler.

(6) Rear stop device: the use of Belgium’s latest design accurate and stable rear stop device, servo motor drive ball screw, with high speed, positioning accuracy characteristics;

(7) Mechanical compensation device: when bending the plate material, the upper skateboard will inevitably produce scratching deformation, so that the bend angle of the work piece is small at both ends, the middle of the large state. This machine is equipped with compensation iron, and through the CNC system control, so that the lower work table produces pre-convex compensation on the skateboard deformation, the angle change of the work piece is controlled in the tolerance range, to ensure high-quality bend accuracy.

(8) Cantilever system: more ergonomic cantilever system, set a reasonable rotation radius, more flexible, more easy to operate.

The oil pump adopts the German VOITH Voith high-performance internal meshing gear pump, with high volume efficiency, low pressure fluctuation, low noise, light weight, wide viscosity range and good oil absorption characteristics.

Product Parameters

| No. | Name | Unit | Valve | |

| 1 | Nominal Pressure | KN | 400 | |

| 2 | Bending Length | mm | 1500 | |

| 3 | Column Spacing | mm | 1100 | |

| 4 | Slider Stroke | mm | 1500 | |

| 5 | Maximum Opening Height | mm | 430 | |

| 6 | Throat Depth | mm | 320 | |

| 7 | Worktable Height | mm | 800 | |

| 8 | Maximum speed of slider running | Drive | mm /s | 200 |

| 9 | Suppress | mm /s | 0.2-50 | |

| 10 | Reverse Drive | mm /s | 200 | |

| 11 | Main Motor Power | KW | 1500 | |

| 12 | Boundary Dimension(L*W*H) | mm | 1900*1500*2300 | |

| 13 | Machine Weight | KG | 3500 | |

Machine models: YDP-PES series Y1, Y2, X, R, Z1, Z2, W (6-1 axis)

Y1Y2-axis—— control slider up and down movement.

X-axis——controls the movement of the rear gear material up and down.

R-axis——Controls the movement of the rear gear material up and down.

Z1、Z2-axis—–Control gear left and right movement.

W-axis——work station compensation.

Key accuracy indicators:

Slider positioning accuracy: Y1, Y2 =±0.02 mm.

Slider repeat positioning accuracy: Y1, Y2 =±0.01 mm.

Bend workman angle tolerance: .±30’/full length.

Re-positioning accuracy of the X-axis of the rear stop material:≤±01mm.