Upper Roll Universal Rolling Machine – Technical Characteristics Analyse

Upper Roll Universal Rolling Machine – Technical Characteristics Analyse

Description

The upper roll universal rolling machine adopts hydraulic transmission for moving the upper roll, hydraulic transmission for the horizontal movement of the lower roll, and electric centralized control operating system. The machine can complete the pre-bending of several rolls at both ends of the plate at one time, and it can also carry out the metal plate. Certain plastic leveling, direct pre-bending, save trouble, save materials, configuration, system control, and improve the degree of automation. This machine is widely used in processing with high precision requirements.

Classification

Universal rolling machines are divided into: large, medium and small.

- Large upper roll universal plate rolling machine

The main features of the large upper roll universal bending machine: unique bending process with superior product accuracy, high-precision end pre-bending, continuous bending without back angle, digital control of the bending process, man-machine dialogue control interface, efficient and intelligent operation of the physical bending process software, Man-machine dialogue window, automatic compensation during bending. Single-person operation, efficient, safe, convenient and rich in curved shapes with rolled O-shaped, U-shaped, multi-segment R and other different shapes.

- Medium-sized upper roller universal plate rolling machine

The main features of the medium-sized upper roll universal bending machine: unique bending process with superior product precision, high-precision end pre-bending, continuous bending without back angle, digital control of the bending process, man-machine dialogue control interface, efficient and intelligent operation of the physical bending process software, Man-machine dialogue window, automatic compensation during bending. Single-person operation, efficient, safe, convenient and rich in curved shapes with rolled O-shaped, U-shaped, multi-segment R and other different shapes.

- Small upper roll universal plate rolling machine

The main features of the small upper roll universal bending machine: unique bending process with superior product precision, high-precision end pre-bending, continuous bending without back angle, digital control of the bending process, man-machine dialogue control interface, efficient and intelligent operation of the physical bending process software, Man-machine dialogue window, automatic compensation during bending. Single-person operation, efficient, safe, convenient and rich in curved shapes with rolled O-shaped, U-shaped, multi-segment R, etc. [1].

Technical characteristics of the upper roll universal rolling machine

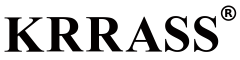

- The drum-shaped upper roller and the lower roller under the lower roller are coordinated and adjusted to achieve high-precision product straightness

Adopting drum-shaped upper roller.The upper roller drum-shaped preset amount is generally 70% of the uniformly distributed load of the roller. The lower roller with a smaller diameter is supported by an up-and-down adjustable idler roller at the lower part of the lower roller. According to the load of the rolled product, adjusting the idler under the lower roller greatly improves the straightness of the product.

- Curved and rolled rear, high-precision roundness

The upper roll universal rolling machine adopts rear bending (the feeding direction of the sheet is opposite to the moving direction of the upper roll). The upper roll is pressed down while the lower roll rotates, continuously bending, and the end of the sheet is directly pre-bent. , to avoid the generation of the front bend angle, and can control the length and shape of the remaining straight sides.

Generally, the three-roll asymmetric type adopts forward bending. First, the two ends of the sheet are pre-bent, and then symmetrically rolled into shape. Skilled operators are required. The product has a back angle and the shape of the remaining straight edges is difficult to control.

- Reduce the amount of product misalignment

The upper roll universal rolling machine has taken the following measures to reduce the amount of product misalignment:

①The dimensional accuracy and shape tolerance of the center distance between the two lower rollers and the two lower rollers are used as key process control;

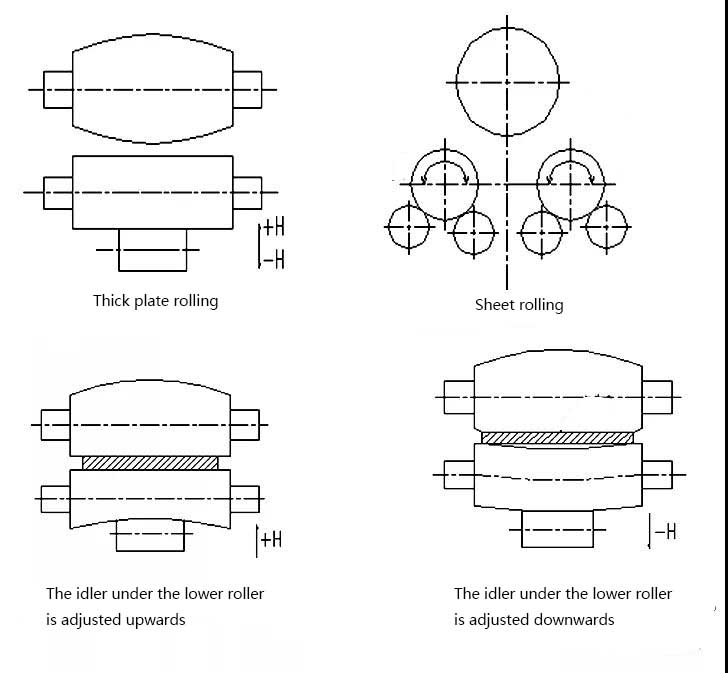

②The synchronous electro-hydraulic combination of the upper roller adopts a feedback system to automatically level.

- High-precision end pre-bending

When the end is pre-bending, the horizontal movement of the upper roller can be changed, and the length of the straight side can be set freely; the upper roller is directly pressurized to control the shape of the straight side to achieve high-precision end pre-bending.

Scope of Application

The machine is widely used in industries with high precision requirements, such as: aviation, nuclear power and other metal structural parts manufacturing industries and chemical machinery, offshore oil platforms, oil, gas and water pipelines and other industries.