W11S plate rolling machine rolling process

W11S plate rolling machine rolling process

1. Turn on the power of the plate rolling machine,

2. Enter the required diameter of the rolled workpiece, the width of the coil, the thickness of the coil, and the end curvature coefficient of the coil into the calculation program. The program will calculate the horizontal displacement X, the upper roll reduction Y1-Y4, and the idler adjustment Measure H, and input the results ±X\Y2(NO1), Y3(NO.2) into the digital display coordinates respectively. For the input method, please refer to the electrical description, and set the preset knob to the ON state.

3. Adjust the inversion of the roller according to the amount of movement of the roller calculated by the program.

4. Give enough lubricating oil to the lubrication place, and add the lubricating oil in the reducer. (It can also be operated manually according to the following steps)

5. Roll the board according to the following method:

Step 1: feed the board and match the material;

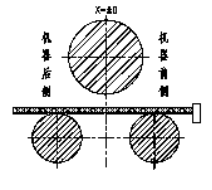

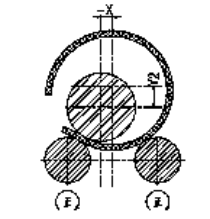

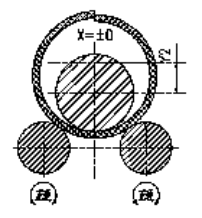

Step 2: the upper roller moves horizontally to the -X position and descends to the Y1 position; the lower roller reverses to make the steel plate to the forming position.

Step 3: the lower roller rotates forward while the upper roller presses down;

Step 4: the upper roller is pressed down to the Y2 position to stop, and the lower roller continuously rotates forward;

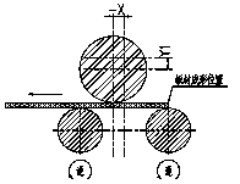

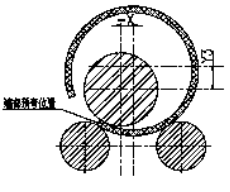

Step 5: Stop at the end of the plate, stop by pressing Y3 on the upper roller, and directly press and pre-bend the end of the plate;

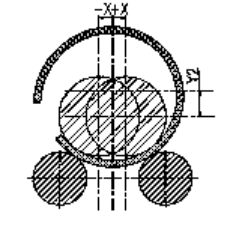

Step 6: The upper roller raises Y2-α, moves horizontally to the +X position, presses down the same position Y2, and the lower roller rotates forward;

Step 7: Stop at the end of the plate, stop at the Y3 position by the upper roller, and directly press and pre-bend the end of the plate;

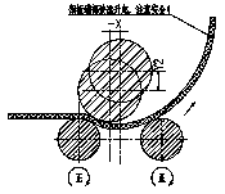

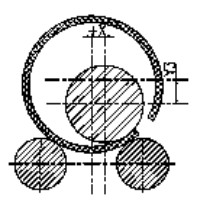

Step 8: Move the upper roller to X=0, press down to the Y4 position, and the lower roller rotates forward and backward to compensate for bending.

Note:

The straight edge of the plate after the equipment indenter is 2-2.5 times the thickness of the plate. If the reel has high precision, it can be welded and rounded by other equipment (such as hydraulic press, etc.) after indenting or cutting the straight edge by gas.

The above is a rolling method, customers can roll the plate according to their own proficient method.